Box Build Assembly Process Step-by-Step: From Components to Final Product

- Harshit Shah

- Jul 10, 2025

- 5 min read

Updated: Jan 3

Box build assembly is a complete process that goes beyond placing electronic components on a printed circuit board. It involves integrating multiple mechanical and electrical elements into a fully operational product that aligns with client specifications.

In today’s industrial and commercial electronics landscape, the demand for reliable and scalable box build assembly services continues to grow. This approach streamlines production by consolidating multiple assembly stages under one roof, improving coordination and consistency across every stage of the build.

In this blog, we break down the step-by-step process, components involved, and the business benefits of partnering with the right box build assembly company, from sourcing to final shipment.

Table of Contents

Key Components Used in the Box Build Assembly Process

The effectiveness of any box build assembly relies on the seamless integration of a wide range of components. These elements come together to form a complete, functional unit ready for end use or further system integration. Each component must meet industry-grade specifications to ensure compatibility, reliability, and performance.

1. Printed Circuit Board Assemblies (PCBAs)

These are the functional core of any electronic product. PCBAs consist of mounted components, such as microcontrollers, power ICs, and communication interfaces. In box builds, they are usually sourced either in-house or from a PCB assembly partner and are the first modules to be tested and installed.

2. Cables and Wire Harnesses

Pre-cut, labeled, and crimped cable and wire harness assemblies form the internal wiring network. They connect submodules, power inputs, and control panels. Precision in wire routing and secure terminations is essential to avoid electrical noise, interference, or mechanical failure during operation.

3. Power Supplies and Modules

Power management components, such as AC-DC converters, battery packs, and regulators, are integrated to ensure stable energy delivery across the system. These units are selected based on voltage, current load, safety ratings, and thermal performance.

4. Electromechanical Components

Fans, solenoids, motors, sensors, relays, and actuators form the active interface between electronic control and mechanical output. Their correct integration ensures the final product performs tasks with efficiency and accuracy.

5. Enclosures and Chassis

The mechanical housing—typically made from metal or industrial-grade plastic—protects internal components from environmental stress, EMI interference, and handling damage. Custom-cut slots, mounting holes, and gaskets are often required to meet IP ratings or industry regulations.

6. Displays, Keypads, and User Interfaces

Many box build units include LCDs, touchscreens, buttons, or status LEDs. These components must be ergonomically positioned, securely mounted, and functionally tested for responsiveness and durability.

7. Software/Firmware Loading Units

When applicable, embedded software is flashed onto controllers or processors during assembly. This requires the integration of test jigs, programming fixtures, and version tracking systems.

8. Cooling and Thermal Management

Depending on the power load, heatsinks, fans, and thermal pads may be installed. These ensure long-term reliability by managing internal temperature fluctuations during device operation.

You May Also Read: A Detailed Guide to Surface Mount Technology (SMT) in PCB Assembly

The Step-by-Step Box Build Assembly Process

A professional box build assembly process is defined by structure, traceability, and quality assurance at each phase. Here is a breakdown of the workflow typically followed by leading electronics manufacturing service (EMS) providers:

1. Component Procurement

All parts—electrical, mechanical, or custom—are sourced based on the approved Bill of Materials (BOM) given by OEM. This includes:

PCB assemblies (tested or bare)

Cables, harnesses, and terminals

Power supplies, control panels, sensors

Enclosures, fans, switches, and fasteners

Procurement also involves validating certifications (RoHS, ISO), verifying lead times, and ensuring traceability for mission-critical industries such as aerospace, transportation, or medical.

2. Subassembly Preparation

To improve efficiency during final integration, pre-assembly tasks are performed:

Cables are cut, stripped, and terminated with appropriate connectors

Fan brackets, button pads, and panel inserts are mounted

Heat shrink, labels, and barcodes are applied where needed

Pre-assembled modules are individually tested to ensure they meet design and functional requirements before moving into final integration.

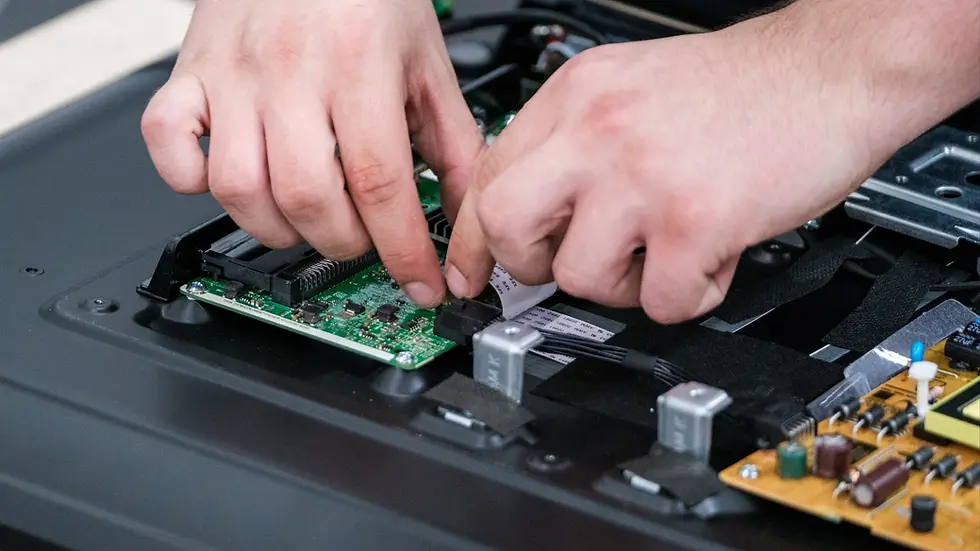

3. Final Mechanical and Electrical Assembly

This stage brings together all individual modules into a unified enclosure:

PCBAs are mounted on standoffs or slots within the chassis

Wire harnesses are routed and secured with clips or cable ties

Connectors, displays, and hardware are installed and fastened

Thermal pads, EMI shielding, and insulation layers are applied

Operators follow detailed work instructions (WI) and standard operating procedures (SOPs) to ensure repeatable, high-quality output.

4. Testing and Quality Assurance

Before shipment, each unit undergoes strict verification:

Power-on tests to confirm voltage and current stability

Functional testing of buttons, displays, and interfaces

Firmware checks, if applicable, to verify correct installation

Continuity, resistance, and insulation testing on wiring

AOI (Automated Optical Inspection) and, in some cases, environmental or vibration tests

Test results are logged, and traceability is maintained for warranty and support purposes.

5. Packaging and Logistics

After passing quality inspection, the product is prepared for delivery:

Devices are packed in static-protected and impact-resistant materials

Manuals, compliance documents, and labels are included per customer specs

Items are serialized, palletized, and shipped directly to the warehouse, distributor, or end customer

Electronics manufacturing company often offer kitting, drop-shipping, and global fulfillment services as part of their box build assembly support.

You May Also Read: A Step-by-Step Guide to the PCB Assembly Process in Electronic Manufacturing

Benefits of Partnering With The Right Box Build Assembly Company

Outsourcing the box build assembly process to a qualified provider offers numerous operational and strategic benefits for electronics manufacturers and system integrators:

1. Streamlined Supply Chain

A reputable box build assembler handles the procurement of components, reducing your supplier count and simplifying your logistics management.

2. Cost and Time Efficiency

An experienced box build assembly manufacturer minimizes delays by managing inventory, testing, and integration in-house, lowering production costs and shortening time-to-market.

3. Design for Manufacturability (DFM) Support

Top providers offer DFM recommendations early in the design process, helping reduce revisions, assembly errors, and rework costs.

4. High Quality and Reliability

Established box build assembly services adhere to industry standards such as ISO 9001, IPC-A-610, and RoHS compliance, ensuring long-term performance and regulatory conformance.

5. Full Turnkey Capability

From PCB box build assembly services to full product integration, packaging, labeling, and logistics, turnkey providers offer end-to-end solutions, freeing your internal team to focus on R&D or marketing.

Conclusion

The box build assembly process combines electronic, mechanical, and software elements to deliver a functional product ready for market deployment. Choosing the right box build partner—with the right tools, certifications, and experience—ensures high-quality outcomes, scalability, and operational excellence.

Looking for a reliable partner to manage your box build manufacturing needs?A2Z Electronics LLC delivers full-service box build assembly services tailored for industrial, medical, transportation , and consumer electronics applications . Get in touch with us to streamline your production and accelerate your time-to-market.