PCB Repair Cost Breakdown: What OEMs Need to Know

- Harshit Shah

- Sep 12, 2025

- 6 min read

Updated: Jan 3

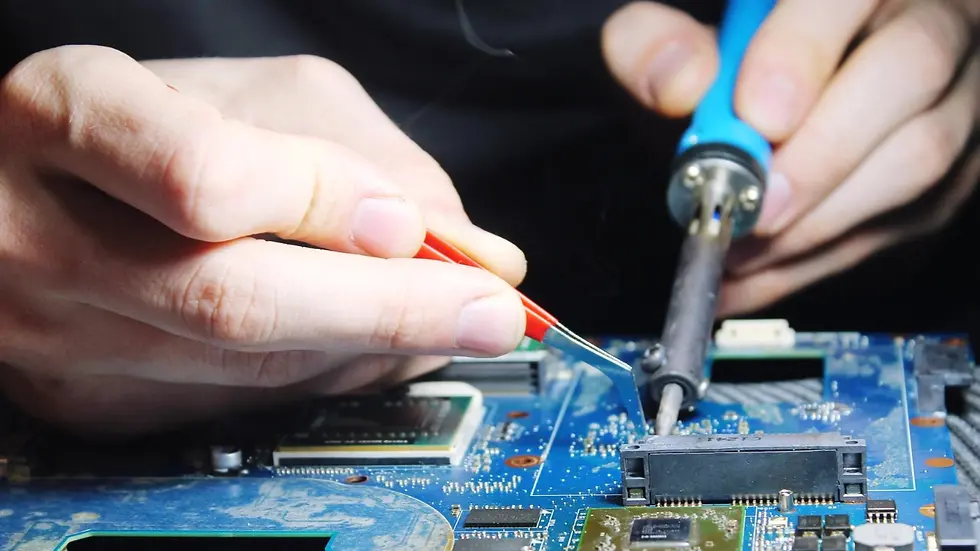

When a Printed Circuit Board fails, OEMs face an important question: repair or replace? While replacement might seem like the simplest option, it can also be the most expensive, especially for specialised or multilayer boards. On the other hand, PCB repair can often restore functionality at a fraction of the cost, but the exact PCB repair cost depends on several technical and logistical factors.

For manufacturers, it’s not just about the invoice for a single repair; it’s about how downtime, hidden expenses, and repair quality affect the entire operation.

In this article, we’ll break down the true cost of printed circuit board repair, compare it to replacement, and give OEMs practical strategies to reduce expenses without sacrificing reliability.

Key Takeaways

The PCB repair cost is influenced by factors like board complexity, fault type, and component availability.

Hidden costs, downtime, logistics, and quality risks can often outweigh direct repair expenses.

Repair vs replacement decisions should consider long-term reliability, availability of parts, and compliance requirements.

OEMs can reduce costs through preventive maintenance, component stocking, and specialist repair partners.

Industry requirements differ: boards used in medical and aerospace demand higher-cost repairs than consumer electronics.

Table of Contents

Key Factors That Influence PCB Repair Costs

The PCB board repair cost is never one-size-fits-all. It varies depending on the complexity of the board, the nature of the damage, and the environment in which it operates.

Board Complexity

A single-layer board used in low-end consumer devices is cheaper to repair than a multilayer or HDI PCB used in medical or aerospace systems. More layers mean more routing paths and greater difficulty accessing faults.

Nature of Failure

A burned-out capacitor or connector is simple to swap out, but faults involving signal integrity, short circuits, or power regulation require advanced diagnostics and significantly more time.

Component Availability

If the failed component is readily available, PCB repair is straightforward. But when components are obsolete or custom-made, costs rise due to procurement challenges or the need for re-engineering.

Testing & Diagnostics

PCB troubleshooting is an essential step in ensuring that repairs actually solve the root problem. Specialised tools like X-ray inspection and thermal imaging add to the cost but are often necessary for high-reliability printed circuit boards.

Labor & Expertise

Skilled technicians are essential for precise rework, especially when boards involve fine-pitch components or require BGA reballing. Naturally, labour rates vary with expertise and region.

Interesting reads: How Much Does PCB Assembly Cost? Breakdown & Tips to Reduce

Hidden Costs OEMs Often Overlook

While the direct PCB repair cost may look reasonable on paper, OEMs often underestimate indirect expenses:

Downtime Costs

Every hour of lost production can translate into thousands of dollars in missed output, making downtime one of the biggest hidden expenses.

Shipping & Handling

Fragile PCBs must be packed, shipped, and insured properly. When boards are sent across borders, customs delays or fees can also add up.

Quality Risks

Opting for cheaper circuit board repair services may reduce the upfront bill, but if repairs fail in the field, warranty claims and product recalls could cost far more in the long run.

Inventory Holding

If boards are under repair for extended periods, OEMs may need to hold extra stock to avoid shortages, tying up working capital unnecessarily.

For OEMs, understanding these hidden costs is just as important as calculating the base repair price.

PCB Repair vs Replacement: Cost Comparison

The decision between PCB repair and replacement often comes down to the total cost of ownership.

Repair

Repairing is generally faster and less expensive, especially for issues like faulty connectors, damaged traces, or replaceable components. Repairs also support sustainability initiatives by extending product life. For example, an AC PCB repair cost is typically much lower than replacing the entire unit.

Replacement

Replacement may be necessary when a board is too severely damaged or when technology is outdated and components are unavailable. For boards that are mission-critical, like those in aerospace or high-end medical devices, replacement may be the only way to ensure compliance and reliability.

OEMs should evaluate not only the immediate cost but also the long-term implications, including warranty obligations, production schedules, and sustainability goals.

Interesting reads: How Much Does PCB Assembly Cost? A Breakdown for Small and Large Orders

Cost-Saving Strategies for OEMs On PCB Repairing

Controlling PCB repair costs isn’t just about finding the cheapest manufacturer; it’s about building smarter repair strategies:

Preventive Maintenance

Regular inspections and testing of board help identify small issues before they become major failures.

Component Stocking

Keeping a buffer stock of high-risk or hard-to-source components helps avoid procurement delays and inflated prices.

Failure Analysis

Understanding why a PCB failed prevents recurring issues and reduces repeat repair costs.

Partnering with Specialists

Working with experienced providers of circuit board repair services ensures repairs are done right the first time, reducing costly rework.

Standardization

Where possible, standardising PCB designs and components across product lines reduces repair costs by simplifying sourcing and troubleshooting.

Industry-Specific Cost Considerations

Different industries experience different cost dynamics when it comes to printed circuit board repair. Here’s how repair costs and considerations vary across the industries we serve

1. Medical Devices

PCB repair in the medical field requires strict adherence to regulatory standards like ISO 13485. These boards often undergo extensive diagnostics and testing before being cleared for reuse.

Estimated Repair Cost: Anywhere around $200 – $500+

Key Cost Drivers: Compliance testing, traceability, cleanroom handling

2. Transportation Systems (Automotive, Railway, etc.)

PCBs in transportation endure vibration, dust, temperature swings, and long usage hours. Repairs often include conformal coating, re-soldering under stress conditions, and ruggedization.

Estimated Repair Cost: $150 – $350

Key Cost Drivers: Environmental durability, high-reliability testing

3. Aerospace Systems

Aerospace PCBs are mission-critical. Repairs demand the highest level of inspection (X-ray, thermal imaging), precision, and documentation, as these boards are used in flight systems, sensors, and defense equipment.

Estimated Repair Cost: $300 – $700+

Key Cost Drivers: Certifications, advanced testing, strict failure analysis

4. Industrial Applications

In industries like manufacturing, robotics, and automation, downtime is the biggest cost. Repair timelines are short, and replacements are urgent. Boards are often high-power or custom-built, adding complexity.

Estimated Repair Cost: $120 – $300

Key Cost Drivers: Speed, power handling, quick component sourcing

5. Lighting Technology

PCBs in lighting systems (LED drivers, smart lighting controls) are typically simpler but operate in varied environments. Repairs are often quick, though aging components and heat exposure can complicate fixes.

Estimated Repair Cost: $80 – $200

Key Cost Drivers: Heat damage, power issues, and connector faults

6. Defense Systems

Like aerospace, PCBs in defense are sensitive, encrypted, and rugged. Repair work is highly specialised and requires documented validation processes. Only certified technicians and secure labs are often authorised.

Estimated Repair Cost: $400 – $800+

Key Cost Drivers: Classified designs, security standards, detailed documentation

How to Choose the Right PCB Repair Partner?

Choosing the wrong partner for PCB repair can lead to repeat failures, delays, and higher long-term costs. OEMs should evaluate potential partners based on:

Technical expertise and ability to handle both PCB troubleshooting and assembly.

Compliance with certifications such as IPC, ISO, and industry-specific standards.

Availability of advanced testing tools like AOI, ICT, and X-ray analysis.

Transparent pricing models without hidden fees.

Strong track record in serving OEMs within the same industry.

Why Choose A2Z EMS for PCB Repair and Assembly?

As a trusted electronics manufacturing company in the USA, we recognise that PCB failures don’t just cost money; they affect customer trust, timelines, and product performance. Our printed circuit board repair services cover the entire process, from diagnostics and sourcing to component-level repair and final testing. With our experience across various industries, including medical, transportation, and consumer electronics, we ensure that every repair meets the highest quality standards.

By partnering with A2Z EMS, OEMs gain more than just cost savings; they gain peace of mind, knowing their boards are repaired by experts who understand the bigger picture of product lifecycle and reliability.

You May Also Read: How to Choose a Reliable PCB Assembly Company for Your OEM Project?

Wrapping Up

Understanding the real drivers of PCB repair cost is critical for OEMs aiming to balance quality with efficiency. By looking beyond the obvious repair bill and considering hidden costs, industry requirements, and repair partner expertise, companies can make smarter decisions that protect both their budgets and their reputations. With the right strategies and the right partner, PCB repair becomes not just a cost, but an investment in long-term reliability.